#How to use 7 QC tools

Explore tagged Tumblr posts

Text

7 QC Tools for Quality Improvement in Manufacturing & Services Industries

In our competitive business climate today, consistently providing a quality product or service is not a choice, it is necessary. Whether in the manufacturing or service industry, the task of fulfilling expectations of a customer requires tools that help you to identify the problem, analyze the data, and the process of improvement. This is where the 7 QC (Quality Control) Tools come into play.

The 7 QC Tools are simple, effective, and applicable to everyone; they are the basis for quality improvement for all industries. Let’s take a look at each of these tools and how quality can provide value to you in your work.

What Are the 7 QC Tools?

The 7 QC Tools are basic statistical tools developed by Kaoru Ishikawa, a Japanese quality expert, to improve product and service quality. They are:

Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flow Chart (Process Mapping)

These tools help teams in problem identification, root cause analysis, monitoring processes, and decision-making — critical to achieving Total Quality Management (TQM) and continuous improvement.

1. Cause-and-Effect Diagram (Fishbone Diagram)

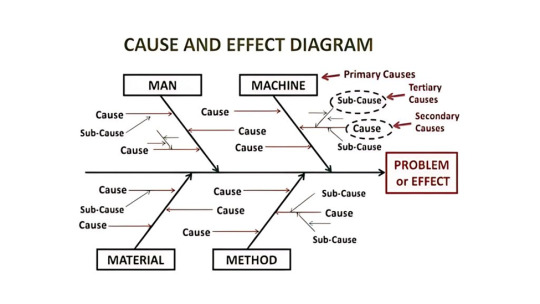

Also known as the Ishikawa Diagram, this tool is used to identify the root causes of a problem by categorizing possible causes into groups such as:

Man

Machine

Method

Material

Measurement

Environment

📈 Use Case:

In a manufacturing plant, if there’s a defect in the product, the Fishbone Diagram helps break down and analyze every possible factor that could be causing it.

In a service company, it could be used to find why customer complaints have increased.

2. Check Sheet

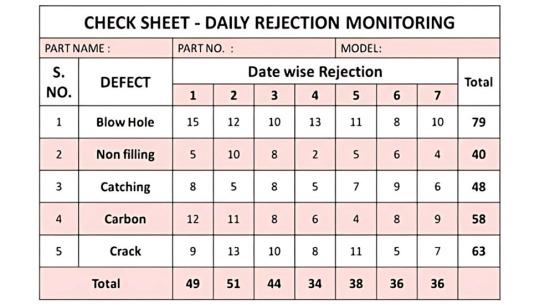

A Check Sheet is a structured, prepared form used to collect real-time data at the location where it is generated. It's one of the simplest and most effective tools for tracking how often a problem occurs.

📈 Use Case:

In manufacturing, it might track the number of defects per shift.

In services, a call center might use it to log the types of issues customers report.

3. Control Chart

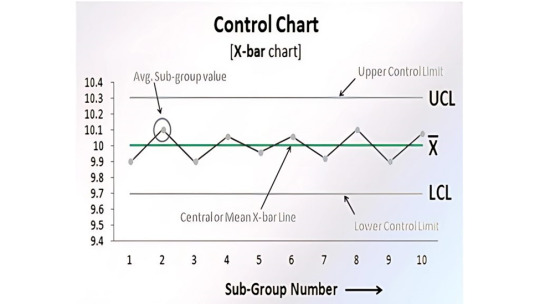

Control Charts are used to monitor process variation over time and determine whether a process is in a state of control.

It distinguishes between:

Common cause variation (normal)

Special cause variation (abnormal)

📈 Use Case:

A manufacturing process using machinery can track the consistency of product dimensions.

In services, a control chart could monitor average call handling time to ensure it stays within set limits.

4. Histogram

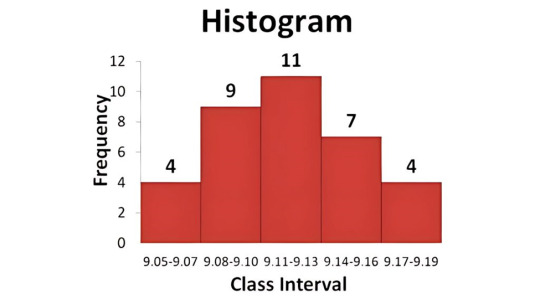

A Histogram is a graphical representation of data distribution. It shows how often each different value in a set of data occurs.

📈 Use Case:

In manufacturing, it helps identify the spread of measurement values, like length or weight.

In services, it can show customer satisfaction ratings to identify performance trends.

5. Pareto Chart

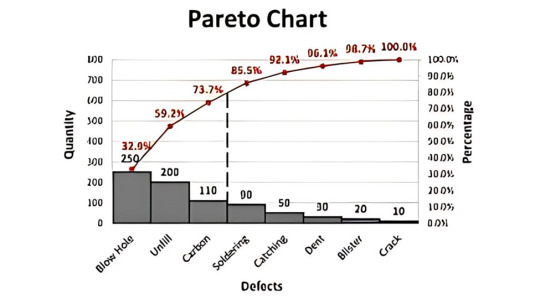

Based on the 80/20 rule, the Pareto Chart helps prioritize problems by showing which causes contribute most to an issue.

It ranks issues from most to least significant, so teams can focus on the "vital few" rather than the "trivial many."

📈 Use Case:

In manufacturing, it helps identify which types of defects occur most frequently.

In services, it can identify the top reasons for customer complaints or service delays.

6. Scatter Diagram

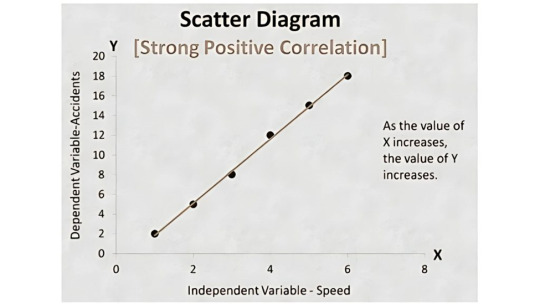

A Scatter Diagram shows the relationship between two variables. It helps determine if a change in one factor affects another.

📈 Use Case:

In manufacturing, you could study the relationship between machine maintenance frequency and product quality.

In services, it might analyze how employee training hours affect customer satisfaction scores.

7. Flow Chart (Process Mapping)

A Flow Chart maps out every step in a process, helping visualize workflows and identify unnecessary steps, delays, or bottlenecks.

📈 Use Case:

In manufacturing, it can map out an assembly process to find inefficiencies.

In services, it can improve the flow of customer onboarding or complaint resolution processes.

Benefits of Using 7 QC Tools in Manufacturing

Reduces defects and rework

Increases productivity and process control

Improves product consistency

Increases the effectiveness of decision making when using data to support decisions

Improves customer satisfaction and retention

Benefits of 7 QC Tools in Services Industry

Improves service delivery time

Reduces customer complaints

Improves employee performance through better processes

Enables proactive problem-solving

Supports a culture of continuous improvement

How to Implement the 7 QC Tools in Your Organization

Step 1: Train Employees

Start with basic training on each QC tool so that employees understand when and how to use them.

Step 2: Identify Problems

Pick a real problem that affects your quality, such as high defect rates or customer dissatisfaction.

Step 3: Choose the Right Tool

Each tool has a unique function. Select based on what you want to analyze — root cause, trends, relationships, etc.

Step 4: Analyze Data

Use the tool to collect and interpret data. Look for patterns, trends, or anomalies.

Step 5: Take Action

Based on the analysis, make informed decisions and implement process improvements.

Step 6: Review & Improve

Monitor the results of your changes and keep refining your processes.

How 4C Consulting Can Help

With experience of working with over 2500+ clients and delivering more than 15,000 hours of quality training, 4C Consulting is your expert partner in implementing QC tools, ISO standards, and quality improvement frameworks.

Our consultants will:

Provide hands-on training on 7 QC Tools

Help create customized checklists, charts, and templates

Assist in integrating these tools into your Quality Management System

Support your team in problem-solving and performance tracking

Ready to improve your quality processes? 👉 Talk to our experts today for a free consultation!

#7 QC Tools#Quality improvement tools#QC tools in manufacturing#QC tools in service industry#How to use 7 QC tools#Basic quality control tools#Problem-solving tools for quality#7 QC tools implementation#Quality management tools

1 note

·

View note

Text

7 QUALITY CONTROL TOOLS FOR PROCESS IMPROVEMENT

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

LIST OF 7 QC TOOLS

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart

Control charts are used to study how the processes have changed over a period of time. Further, by comparing current data to historical control limits, one could lead to the conclusion about whether the process variation is consistent as in under control or unpredictable as in out of the control due to being affected by special causes of variation.

Pareto Chart

Pareto Chart is based on the 80/20 rule where it shows the significant factors that have the highest impact on the identified problem.

Check Sheet

Check sheet is a structured process which helps to collect and analyzing data. It is an effective tool that can be for a variety of purposes.

Histogram

Histogram is commonly used a graph that shows the data and its frequency of distribution to help users identify each different value in a set of data occurs.

Scatter Diagram

Scatter diagram shows the relationship between two important factors i.e. pairs of numerical data, one variable on each axis to demonstrate the relationship.

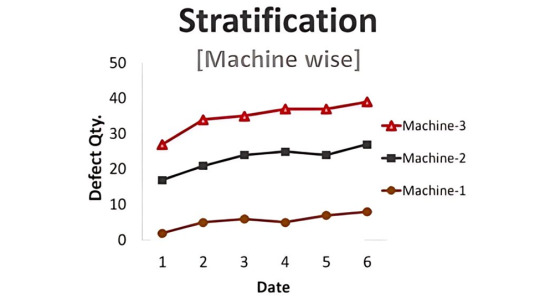

Stratification

Stratification also known as a flow chart or run chart is a technique that separates the data gathered from a variety of sources so that patterns can be seen i.e., the path an entity has taken through a defined process.

Utilizing the 7 QC tools in six sigma or quality management process helps in taking a systematic approach to identify and understand the risk, assess the risk, control fluctuation of product quality and accordingly provide solutions to avoid future defects.

WHEN SHOULD YOU USE 7 QC TOOLS?

7 QC tools can be carried out during the quality management, quality improvement process, six sigma implementation processes or even the regular PDCA cycle for the quality purpose for enhanced quality management.

In the first phase of measuring and identifying, Fishbone Diagram also known as cause and effect diagram, Pareto Chart and Control Chart can be utilized. In the next phases of assessment and analysis, Scatter Diagram, Histogram and Checklist can be carried out. The Control Chart can be utilized consistent quality improvement.

BENEFITS OF 7 QC TOOLS

The 7 QC tools are structured and fundamental instruments that help businesses improve their management and production process for achieving enhanced product quality.

From assessing and examining the production process, identification of key challenges and problems to controlling the fluctuation present in the product quality and providing solutions for prevention of defects in future, the easy to understand and implement, 7 QC tools are very effective. Some of the major business benefits of 7 QC tools are listed below.

Provides a more structured path for problem-solving and quality improvement

Easy to understand as well as implement yet extremely effective

A scientific and logical approach for problem-solving

Follows the 80/20 rule i.e. gain 80% result with 20% efforts

Improve the quality of product and services

Helps in identifying and analyzing problems during the process

Fishbone training aides in root cause analysis and problem-solving

Encourages team spirit and fosters a healthy culture

Identifies roots cause and solve it permanently

Enhance customer experience and customer satisfaction

Based on the data-driven process and customer-centric approach, 7 QC tools implementation is one of the most effective processes that too in the shortest amount of time.

4C team of certified professionals has provided 80+ implementation of 7 QC Tools and 120+ 7 QC Tools Training. By solving 200+ quality problems, 4C has empowered clients to reduce the 80% cost of poor quality. To accelerate your quality management process and reduce your cost of poor quality, contact our experts now.

#iso certification#iso certification consultants#iso consultancy#iso consultant#iso certificate online#iso certification in india

3 notes

·

View notes

Text

How to Keep Your Check Sheet in 7 QC Tools Current and Move It Forward

In the world of quality control and continuous improvement, the 7 QC tools are the foundation for solving problems and enhancing processes. Among these tools, the Check Sheet in 7 QC tools is one of the simplest yet most powerful methods for collecting real-time data in a structured, visual format.

However, just creating a check sheet once isn’t enough. To keep it valuable and relevant, you must update, improve, and align it with your changing process needs. In this blog, we’ll explore how to keep your Check Sheet current and how to enhance its effectiveness over time.

✅ Why Check Sheets Matter in Quality Control

A Check Sheet helps collect data at the source—during inspections, operations, or even customer service. It’s a tool to track:

Defects and error types

Equipment failures

Downtime causes

Frequencies of events

Inspection results

Used correctly, it helps teams spot trends, make decisions based on evidence, and take corrective actions. But if the format is outdated or misaligned with current operations, it loses effectiveness.

✅ Steps to Keep Your Check Sheet Current and Effective

1. Revisit Your Quality Objectives

Begin by asking: What are we trying to measure or control?

As business priorities shift—new product lines, new machines, or different customer complaints—your Check Sheet must reflect those changes. Update your data categories, frequencies, and timeframes to match your current quality goals.

2. Validate the Categories and Data Points

Are you still tracking the right issues? A Check Sheet created months ago may be collecting data that’s no longer useful.

✔ Eliminate outdated categories ✔ Add new defect types or failure modes ✔ Clarify ambiguous terms ✔ Ensure frontline operators understand each category

3. Keep the Format Simple and Clear

A cluttered or confusing Check Sheet leads to inconsistent data collection. Stick to these principles:

Use plain language

Keep columns/rows organized

Avoid excessive detail

Use tick marks or symbols for faster recording

Consider using digital versions (spreadsheets or apps) for efficiency

4. Align Check Sheets with Process Changes

Have you changed tools, materials, or workflows recently?

Update your Check Sheet to reflect these adjustments. For example, if you’ve introduced automation, you might need to track machine error codes instead of manual defects.

5. Standardize Across Shifts and Teams

Inconsistent data ruins trend analysis. Make sure everyone uses the Check Sheet the same way by:

Providing short training or refresher sessions

Using standardized formats across shifts and departments

Clarifying who fills it out and when

Reviewing entries regularly for completeness

6. Review Data Trends and Take Action

A Check Sheet isn’t valuable unless you do something with the data.

Summarize data weekly or monthly

Identify defect patterns, peak times, or recurring failures

Share findings with relevant teams

Link data to corrective actions, Kaizen events, or root cause analysis

7. Digitize for Better Insights

While paper-based Check Sheets are still useful, digital versions offer advantages like:

Real-time data capture

Easy filtering and analysis

Automatic charts and graphs

Remote sharing with quality teams

Consider using tools like Excel, Google Sheets, or quality management software.

✅ When to Revise or Replace Your Check Sheet

Your Check Sheet may need a revamp if:

The same issues have been solved and no longer occur

New types of defects are emerging

Operators complain it’s too complicated

The data collected isn’t helping decisions

The process being monitored has changed

Don’t be afraid to revise or rebuild your Check Sheet—it’s a living tool.

✅ Benefits of Keeping Your Check Sheet Updated

Ensures accurate, real-time data collection

Helps identify trends before they become major issues

Supports faster problem-solving

Increases operator engagement and ownership

Provides valuable input for other QC tools like Pareto Charts or Control Charts

✅ Conclusion

A Check Sheet may look simple—but when updated and used effectively, it becomes a powerful tool for improving quality. By regularly reviewing and refining it, you ensure it continues to support real-time decision-making, reduce defects, and drive continuous improvement.

Remember, in the spirit of the 7 QC tools, quality is not a one-time act—it’s a habit.

#7QCTools#CheckSheet#QualityControl#ContinuousImprovement#ProcessImprovement#QualityManagement#DataDriven#ManufacturingExcellence#QualityAssurance#RootCauseAnalysis

0 notes

Text

Outsourcing Shop Drawing Services: Key Considerations for Choosing the Right Partner

As architectural, engineering, and construction (AEC) projects become increasingly complex and deadline-driven, outsourcing shop drawing services has emerged as a strategic move for many firms. By collaborating with specialized service providers, companies can access expert resources, improve turnaround times, and reduce in-house operational burdens.

However, not all outsourcing partners offer the same level of quality, reliability, and value. Choosing the right partner requires careful assessment across multiple criteria.

What Are Shop Drawing Services?

Shop drawings are detailed plans, diagrams, and schedules developed by contractors, fabricators, or manufacturers. They translate design intent into constructible components, playing a crucial role in ensuring that architectural, structural, and MEP (mechanical, electrical, plumbing) elements align on-site.

Types of shop drawings include:

Architectural shop drawings

Structural steel and rebar detailing

HVAC, electrical, and plumbing drawings

Millwork and cabinetry shop drawings

Precast concrete drawings

Curtain wall and façade systems

These drawings are often required for approval before fabrication or installation and must comply with industry codes and project specifications.

Why Outsource Shop Drawing Services?

Outsourcing shop drawings has grown in popularity due to numerous benefits. When done right, it enhances operational efficiency and accuracy.

Key benefits include:

Cost efficiency: Reduces in-house labor and infrastructure expenses.

Access to expertise: Gain access to a pool of experienced drafters and engineers.

Faster turnaround: Meet tight deadlines with around-the-clock support.

Scalability: Easily ramp up or down based on project volume.

Focus on core functions: Let your team focus on design and construction management.

What to Look for in an Outsourcing Partner

When evaluating potential outsourcing partners for shop drawing services, it's essential to look beyond cost. The right partnership is built on quality, trust, and performance.

1. Technical Expertise and Domain Knowledge

A competent partner must have strong industry-specific knowledge and expertise in drafting tools.

Look for:

Experience with AutoCAD, Revit, Tekla, SolidWorks, and other tools

Industry-specific knowledge (steel detailing, HVAC systems, etc.)

A team of qualified engineers, architects, and drafters

Familiarity with international building codes and standards (e.g., AISC, ASME, NFPA, etc.)

Questions to ask:

How many years of experience do they have in your project domain?

Can they share a portfolio of similar completed work?

2. Quality Assurance and Accuracy

Precision is paramount in shop drawings, as errors can lead to costly delays and on-site rework.

Ensure your partner has:

A structured quality control (QC) process

Multi-layered reviews by senior engineers

Software-aided clash detection and validation

Ability to adapt to project-specific quality checklists

Tips:

Request sample drawings to evaluate drawing consistency and detail quality.

Check for ISO certifications related to quality management.

3. Turnaround Time and Scalability

Timely delivery is critical, especially in fast-paced construction projects.

Consider these factors:

Average turnaround time for various drawing types

Ability to meet short deadlines and handle high-volume tasks

Time zone compatibility and work shift alignment

Availability of resources for ramping up as needed

Checklist:

Does the partner offer 24/7 support or flexible schedules?

Can they provide a dedicated project team?

4. Communication and Project Management

Clear, consistent communication is a cornerstone of successful outsourcing.

Check for:

Assigned project managers or points of contact

Regular updates and progress reports

Use of project management tools like Asana, Trello, or BIM 360

Capability to handle change requests and scope variations smoothly

Best Practices:

Set expectations for response times and meeting frequencies.

Use collaborative platforms for sharing files and revisions.

5. Data Security and Confidentiality

Your design data and intellectual property are sensitive and must be protected.

Evaluate their security measures:

Use of secure file transfer protocols (SFTP, VPN, encrypted cloud services)

NDA agreements and IP protection clauses

ISO 27001 or similar information security certifications

Restricted access to project data on a need-to-know basis

Security checklist:

Where is the data stored and who has access?

What happens to the data post-project?

6. Pricing and Contract Flexibility

Cost is important, but it shouldn't be the only factor. A clear, competitive, and fair pricing model is essential.

Look for:

Transparent pricing (hourly, per drawing, or fixed cost)

No hidden fees for revisions or urgent deliveries

Flexible contracts (short-term, long-term, or per-project basis)

Discount models for bulk work or repeat projects

Budget tip:

Compare multiple vendors, but weigh pricing against quality and turnaround.

7. Past Client Reviews and References

Social proof is a strong indicator of a partner’s reliability and credibility.

What to check:

Client testimonials or case studies

Google reviews or third-party platforms (like Clutch, GoodFirms)

References or contacts from completed projects

Ask directly:

What is their client retention rate?

Can they connect you with past clients for feedback?

Red Flags to Avoid

Even with an impressive pitch, some vendors may not meet expectations. Watch out for:

Overpromising on unrealistic timelines or pricing

Lack of domain-specific samples or references

Poor English or communication breakdowns

Vague contracts with ambiguous deliverables

No clearly defined QC process or project plan

Being vigilant about these red flags helps you steer clear of unreliable partners.

How to Streamline the Outsourcing Process

Once you've selected a partner, optimizing the workflow ensures better outcomes.

Steps to follow:

Define scope and deliverables clearly: Include formats, layers, standards, and any unique requirements.

Share reference files: Models, CAD files, architectural plans, and markups.

Set up a communication routine: Daily standups or weekly updates help maintain alignment.

Use collaborative platforms: Tools like BIM 360, Autodesk Construction Cloud, or Slack help improve visibility.

Monitor performance: Use KPIs such as accuracy, turnaround, and responsiveness.

Future Trends in Shop Drawing Outsourcing

As AEC industries evolve, outsourcing partners must stay ahead of trends like:

Integration with BIM and VDC workflows

Use of AI-powered drafting tools and automation

Cloud collaboration for real-time updates

Sustainability-focused designs

Greater adoption of ISO and LEED-compliant drawing practices

Partnering with forward-thinking service providers helps future-proof your operations.

Final Thoughts

Outsourcing shop drawing services can significantly boost your project efficiency, reduce costs, and provide specialized expertise when done with the right partner. However, due diligence is critical. From technical capabilities and turnaround times to security and communication, a detailed evaluation framework is essential before onboarding any vendor.

Treat the process not as a simple transaction but as a strategic alliance. A reliable outsourcing partner doesn’t just deliver drawings—they contribute to your project’s success by ensuring quality, consistency, and clarity throughout the construction lifecycle.

0 notes

Text

Still Following Up with Vendors on WhatsApp? Streamline Everything with VMS

Managing vendors through WhatsApp messages, endless calls, and scattered spreadsheets might seem quick at first—but over time, it leads to delays, miscommunication, and missed opportunities. If your procurement or supply chain team is constantly chasing vendors for quotes, order status, and payment clarifications, it’s time to upgrade to a Vendor Management System (VMS).

In this blog, we’ll explore the common vendor-related challenges businesses face and how a modern VMS like BETs can streamline, centralize, and automate your vendor operations—from onboarding to invoice settlement.

The Problem with Managing Vendors Over WhatsApp & Excel

Relying on WhatsApp or manual tools for vendor coordination often leads to:

Untraceable Conversations Crucial details like quoted rates, delivery schedules, or order confirmations get lost in chat history.

Manual Errors Mistakes in rate entries, PO mismatches, or unrecorded agreements become common.

No Performance Tracking There’s no real way to evaluate vendor performance over time.

Delayed Approvals & Follow-Ups Cross-department coordination slows down because there’s no structured workflow.

Compliance Issues KYC documents, contracts, or certification renewals are often outdated or missing.

How Vendor Management Software (VMS) Solves These Issues

A modern VMS brings all vendor-related activities under one integrated platform. Here’s what BETs VMS offers:

1. Centralized Vendor Onboarding & KYC

No more sending KYC forms over email or storing documents in scattered folders. Vendors can:

Upload company documents via their login

Submit GST, PAN, bank details, certifications

Receive onboarding status updates

And you stay compliant with a complete digital trail.

2. Catalog & Rate Management

Vendors can manage their product/service catalog, update prices, and share special rate contracts—all in one place. You can:

Compare quotes across vendors with RFQ analysis

Set valid-from/to pricing

Avoid price mismatch issues at PO generation

3. Smart RFQ & PO Tracking

Raise RFQs with ease and track responses in real-time. Once approved, the VMS:

Converts RFQ to Purchase Order automatically

Sends PO notifications to vendors

Allows vendors to accept/reject or comment on POs

No more WhatsApp messages asking “Have you received the PO?”

4. Real-Time Order & Delivery Tracking

Vendors can update dispatch details, vehicle info, and expected delivery time from their panel. You can:

Monitor delivery timelines

Manage vehicle entry at the security gate

Integrate with QC module for incoming inspection

5. Vendor Performance Matrix

Track performance across metrics such as:

On-time delivery %

Quality rejections

Price competitiveness

Response time on RFQs

Use the insights to negotiate better, optimize supplier base, or even reward your top vendors.

6. Payments, Invoice Booking & Settlement

Vendors can upload invoices directly against delivered POs. The system lets you:

Validate invoices with GRN (Goods Receipt Note)

Track payment status (Pending, Processed, Paid)

Avoid disputes and endless follow-ups

7. Document Management & Compliance Alerts

Get auto-reminders for:

Contract renewals

Expiring certifications

Compliance document re-submissions

All stored securely and accessed instantly.

Seamless Integration with ERP & Other Systems

BETs VMS integrates seamlessly with your existing ERP or procurement modules, ensuring that:

Purchase, finance, QC, and stores departments stay aligned

No duplicate data entry

Reporting is real-time and accurate

If you’re still following up with vendors on WhatsApp, you're not just wasting time—you’re also risking data errors, compliance failures, and missed cost-saving opportunities.

BETs Vendor Management Software empowers businesses with a structured, automated, and intelligent platform to manage the complete vendor lifecycle. From onboarding to evaluation, it’s all streamlined—so your team can focus on strategic procurement, not repetitive coordination.

Ready to Upgrade?

Book a free demo to see how BETs VMS can revolutionize your vendor ecosystem. Let your WhatsApp stay personal—leave vendor management to professionals.

To know more,

Visit Us : https://www.byteelephants.com/

0 notes

Text

Sigmund Jähn & the Interkosmos Jahn

1. A Cold-War dream takes flight

On 26 August 1978, East-German fighter pilot Sigmund Jähn blasted off aboard Soyuz 31 with commander Valeri Bykovsky, becoming the first German ever to leave Earth’s atmosphere. The pair docked with the Salyut 6 space station, carried out 25 experiments, completed 124 orbits, and returned to Earth in Soyuz 29 after 7 days, 20 hours, and 49 minutes aloft. Jähn’s feat earned him the title Hero of the Soviet Union and a place in European space-flight history.

2. The original Interkosmos watch

While Western astronauts famously wore Omega Speedmasters, cosmonauts in the Soviet Interkosmos programme relied on rugged East-Bloc tool watches. Jähn’s personal choice—produced in the Ruhla watch factories of the German Democratic Republic—proved that German engineering could survive launch vibration, micro-gravity, hard vacuum, and wild temperature swings. The story of that watch became inseparable from Jähn’s legacy.

3. Re-issuing a legend: TUW Ruhla Interkosmos Jahn Limited Edition

Today, TUW Ruhla has recreated the space-faring timepiece in partnership with Jähn’s estate, and GDG Watch has secured an exclusive allocation. Key specs include: Feature Modern Spec Why it matters Movement Miyota 9015 automatic High-beat, hacking & hand-winding—rock-solid reliability. Crystal Sapphire-coated Scratch resistance far beyond the mineral glass of the 1970s. Case & Bracelet Solid 316L steel, rivet-style 20 mm bracelet Authentic tool-watch feel with contemporary build. Water resistance 100 m / 10 ATM Ready for everyday adventures, not just zero-g. Warranty 3 years Outclasses the industry’s standard two-year coverage.

The dial proudly carries the Interkosmos emblem, while a commemorative case-back references the Soyuz 31 mission. Each piece is assembled in Germany and offered in two colourways—Classic and DLC-Black—at an introductory price of USD 349 (down from 599) while stock lasts.

4. Why collectors are racing for checkout

Genuine space provenance – Direct homage to the watch worn on the first German spaceflight.

Strict limited production – Once the final units ship, the Interkosmos Jahn will never be made again.

Everyday usability – 40 + hours of power reserve and 100 m WR mean you can actually wear your collectible.

German assembly & QC – Built in the same Thuringian town that equipped cosmonauts in 1978.

Value proposition – Comparable space-themed Swiss pieces run well north of USD 1 000; TUW Ruhla keeps it accessible.

5. Frequently asked questions

Is this the exact watch Jähn wore? No—his flown piece sits in a museum—but TUW Ruhla used factory drawings and Jähn’s personal input to create an authentic modern rebuild with upgraded materials.

How many will be produced? TUW Ruhla has capped the run; once it sells out, the tooling is retired. (GDG Watch shows real-time stock on the product page.)

Does the Miyota 9015 need a battery? Never—its rotor winds the mainspring with every wrist movement, just like 1970s cosmonaut watches.

Can I swim with it? Yes. The screw-down crown and 100 m rating protect against pool laps and daily splashes, though professional diving isn’t advised.

6. Own your slice of space history

Sigmund Jähn proved that the pursuit of the stars transcends borders. The Interkosmos Jahn Limited Edition lets you wear that spirit on your wrist—robust enough for life on Earth, rare enough for any serious watch box.

0 notes

Text

IATF 16949 Consultants: QC Tools Used in the Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

This is no different for Quality Control (QC) tools, the backbone of any quality management system. These tools assist in issue identification, data analysis, process control, and decision-making based on facts. When coupled with QC tools, consultants help organizations that want to achieve compliance with the certification and improve their quality systems to lay a rock-solid foundation to achieve this.

What is IATF 16949?

IATF 16949 in UAE is a technical specification founded by the International Automotive Task Force (IATF) and the International Organization for Standardization (ISO). They based it on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing.

The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Key Objectives:

Benefits of Certification:

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Who Are They?

Consultants are subject-matter experts with proven track records in assisting successful rollout and maintenance of standards within organizations.

Services Provided:

Benefits of Hiring a Consultant:

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

The 7 Basic QC Tools:

Tools Related to Advanced Quality Planning (Core Tools):

The Role of QC Tools in the Quality Systems:

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Common Obstacles:

How IATF 16949 Consultants Help in Dealing with Challenges?

The Main Point!!

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

Instagram – B&Q 12 Days of Christmas Giveaway (Day 12) – Prize Draw Terms and Conditions – 12/12/2024

The Promoter:

B&Q Limited, B&Q House, Chestnut Avenue, Chandler’s Ford, Eastleigh, SO53 3LE

Who can enter?

This promotion is open to all residents of the UK aged 18 years and over, excluding employees of B&Q Limited, their families, agents or anyone else connected with the promotion.

How to enter?

For your chance to enter and win all of the below, simply like this post and comment to tell us what DIY tasks you’re hoping to finish before the big day 🎅

Entries must be received by 23:59 on 12th December 2024. Any entries received after this date will not be accepted.

Entry:

Only one entry per person will be accepted. Third party or multiple entries by the same person will not be accepted and we reserve the right to disqualify any entries we reasonably suspect to have been made fraudulently including through the use of bots, computer software or by any other means. We accept no responsibility for any lost, damaged or incomplete entries or entries not received due to a technical fault or for any other reason beyond our reasonable control.

Prize details:

There will be 1 winner selected. The winners will receive the following prize:

1 x Erbauer Connecx Modular Storage Polypropylene (PP) Toolbox

1 x Erbauer EXT 18V Cordless Jigsaw (Bare Tool) - EJS18-Li

1 x Erbauer EXT 18V Cordless Random orbit sander (Bare Tool) - ERO18-Li

1 x Erbauer EXT 18V Cordless Multi tool (Bare Tool) - EMT18-Li-QC

1 x Erbauer 113 piece Multi-purpose Drill bit set

1 x Erbauer EXT 18V Li-ion Cordless Combi drill & impact driver (2 x 2Ah) - EID18-Li

1 x Erbauer 50 piece Multi-purpose Drill bit set

1 x GoodHome Big box Decorating set, 18 pieces

1 x Erbauer 3 piece Adjustable wrench set

1 x Erbauer 6 piece Standard Mixed Screwdriver set

1 x Erbauer Carbon steel Claw Hammer

1 x Erbauer Tape measure 5m

1 x Erbauer 255mm Torpedo Spirit level

1 x mystery value B&Q gift card (value between £25 - £100)

The prize is non-transferable or exchangeable and no alternative is available. We reserve the right to replace the prize with a prize of equal or greater value where it becomes necessary to do so.

Winner selection and prize fulfilment:

1 winner will be selected at random from all valid entries received.

The winner will be contacted via response to their winning comment by 5pm on the 13th December 2024. To receive the prize, the winner will need to respond via private message providing their contact details. If the winner fails to provide their contact details within 7 days of initial contact from the Promoter, the prize will be offered to the next randomly chosen entrant.

Your Data:

We will process information about entrants in order to administer this promotion. For more information on how we use personal information, please see http://www.diy.com/customer-support/policies/privacy. By entering this promotion, you agree and consent to the processing of your personal data by us and by any third party acting on our behalf for the purposes of the administration and operation of the promotion.

Please note that we are obliged to either publish or make available on request the surname, county and, where applicable, the winning entry/entries of major prize winners. If you object to any of this information being made available in this way, please contact [email protected]. We must nevertheless share this information with the Advertising Standards Authority where it becomes necessary to do so.

Your acceptance of these Terms:

We reserve the right to refuse entry or refuse to award any prize to anyone in breach of these Terms and Conditions and/or hold void, cancel, suspend or amend these Terms and Conditions where it becomes necessary to do so. Our decision on all matters relating to this promotion is final and binding. No correspondence will be entered into.

Liability:

By entering this promotion, you are deemed to have accepted and agreed to be bound by these Terms and Conditions.

Insofar as is permitted by law the Promoter and its agents and distributors will not in any circumstances be responsible or liable to compensate the winner or accept any liability for any loss, damage, personal injury or death occurring as a result of taking up the prize except where it is caused by the negligence of the Promoter, its agents or distributors or that of their employees.

This promotion is in no way endorsed or administered by or associated with Instagram or Meta.

Governing Law:

Nothing in these Terms and Conditions restricts your statutory rights as a consumer. This promotion will be governed by English law and entrants submit to the jurisdiction of the English Courts.

0 notes

Text

The Future of Quality Management: How Will the 7 QC Tools Evolve with AI and Automation?

The seven quality control tools (7 QC tools) have been a cornerstone of quality management for decades. These simple yet effective tools, including Pareto charts, histograms, check sheets, cause-and-effect diagrams, flowcharts, stratified charts, and scatter diagrams, have helped organizations identify and address quality issues. As technology continues to advance, particularly with the rise of artificial intelligence (AI) and automation, it's imperative to explore how these tools will evolve and enhance quality management practices.

The Impact of AI on Quality Management

AI has the potential to revolutionize quality management by automating tasks, improving data analysis, and providing predictive insights. Here's how AI can enhance the 7 QC tools:

Data Collection and Analysis:

Automated data collection: AI-powered systems can collect data from various sources, including sensors, machines, and databases, in real-time. This eliminates manual data entry errors and ensures data accuracy.

Advanced data analysis: AI algorithms can analyze vast datasets to identify patterns, trends, and anomalies that would be difficult or time-consuming for humans to detect. This enables organizations to pinpoint root causes of quality issues more efficiently.

Predictive Maintenance:

Predictive analytics: AI can analyze historical data and identify potential failures before they occur. This allows for proactive maintenance, reducing downtime and improving overall product quality.

Optimized maintenance schedules: AI can help determine the optimal frequency and scope of maintenance tasks based on real-time data and predictive models.

Process Optimization:

Process simulation: AI can simulate various process scenarios to identify bottlenecks, inefficiencies, and potential improvements.

Automated process adjustments: AI can automatically adjust process parameters in real-time to optimize performance and minimize defects.

The Role of Automation in Quality Management

Automation, in conjunction with AI, can further enhance the 7 QC tools by streamlining tasks and reducing human error. Here are some key areas where automation can make a significant impact:

Inspection and Testing:

Automated inspection systems: AI-powered vision systems can inspect products for defects at high speed and accuracy, reducing the need for manual inspection.

Automated testing: Automation can be used to perform various tests, such as functional testing and performance testing, more efficiently and reliably.

Defect Tracking and Analysis:

Automated defect tracking: AI can automatically track and categorize defects, making it easier to identify trends and root causes.

Automated root cause analysis: AI can use data mining techniques to analyze defect data and identify potential root causes.

The Evolving 7 QC Tools

As AI and automation continue to advance, the 7 QC tools are likely to evolve in the following ways:

Integration with AI and automation platforms: The tools will become more seamlessly integrated with AI and automation platforms, allowing for more efficient data collection, analysis, and decision-making.

Enhanced visualization capabilities: AI can create more sophisticated visualizations, making it easier to understand complex data and identify trends.

Predictive analytics and modeling: The tools will incorporate predictive analytics and modeling techniques to enable proactive quality management.

Real-time monitoring and control: AI-powered systems can provide real-time monitoring of quality metrics and enable automated control of processes.

In conclusion, the future of quality management is bright with the integration of AI and automation. By leveraging these technologies, organizations can enhance the effectiveness of the 7 QC tools and achieve new levels of quality excellence. As AI and automation continue to evolve, it is essential for quality professionals to stay updated on the latest developments and explore how these technologies can be applied to their specific needs.

0 notes

Text

Understanding the 7 QC Tools: The Foundation of Quality Improvement

In every quality-based company, problem-solving involves going beyond just resolving an issue. It requires deep diving into understanding why the issue arose in the first place. This is exactly where the 7 Quality Control (QC) Tools come into play.

Designed in Japan, these tools offer a practical, visual, and data-oriented method for problem-solving, analysis of processes, and continual improvement. Be it managing production lines, performing compliance audits, or spearheading digital transformation projects, the 7 QC Tools assist teams in clearly and systematically eliminating root causes, minimizing variation, and improving performance.

All seven tools contribute to the enhancement of evaluating processes and inefficiencies for the sake of achieving ongoing operational excellence. Their collective application builds a comprehensive system that can be used in any field, including but not limited to, healthcare, logistics, and information technology.

The 7 QC Tools for Quality Improvement

These tools form the foundation of any successful Quality Management System (QMS). Their straightforward nature as well as flexibility make them indispensable for any team that aims at building a culture of quality.

1. Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

This tool aids in outlining every potential cause a given problem may have. By grouping causes into manpower, methods, machines, measurement, materials measurement and environment, teams deepen their understanding of the issue.

Example: A sealing two-hundred boxes of country's best raw honey fails repeatedly. A packaging team takes this diagram to help overcome this issue.

2. Check Sheet

As simple as it gets, check sheets allow customers to identify all types of orders, including defects, errors, and occurrences systemically.

Example: A logistics company tracks and identifies peak periods for late deliveries using check sheets.

3. Control Chart

A process is stable when the control upper and lower limits are constant, while in need of corrective action when they change. Control charts display process behavior over time.

Example: A pharmaceutical company control charts to avoid inconsistent temperature control during production.

4. Histogram

Example: IT support teams resolve tickets and average the time taken to do so.

5. Pareto Chart

Example: A call center finds out that two service lines account for a majority of customer complaints through Pareto analysis.

6. Scatter Diagram

Example: An HR manager tests a theory about onboarding hours and early-stage employee error reduction by increasing onboarding hours.

7. Flowchart

A flowchart is one of the ways to visualize processes step-by-step. It helps teams pinpoint inefficiencies, bottlenecks, and redundancies.

Example: A hospital maps out its discharge process to identify and eliminate delays.

Where Can These Tools Be Used?

Finally, all industries can use the 7 QC tools, even if they were primarily used in manufacturing.

In ESG compliance: Monitor sustainability KPIs and supplier risk.

In HR: Streamline hiring and employee performance monitoring using flowcharts and control charts.

In IT: Use histograms and Pareto charts to improve response times for help desk services and reduce system outages.

In logistics: Identify service-related delays, optimize routes, and improve service.

These tools allow all organizations, regardless of industry, to practice fact-based decision making, which is crucial in any organization committed to quality.

How to Implement the 7 QC Tools Effectively

The good news is that you don't need expensive tools and certifications to start. Most of these can be implemented using Excel, Google Sheets, or even pen and paper.

Steps to Implement:

1. Identify the problem – Frame the issue you are experiencing as specifically as possible.

2. Select the right QC Tool – Match the problem or analysis with the appropriate tool.

3. Train your team – Make sure the relevant personnel know how to use the selected tools.

4. Collect accurate data – Focus on achieving consistency as well as completeness.

5. Analyze and act – Review all the data and decide what information will lead to improvement.

With some support from leadership and basic training, these tools can easily be integrated into your team's daily routines and problem-solving habits.

Why the 7 QC Tools Matter

The 7 QC tools are incredibly powerful due to how basic they are. They:

• Enable root cause analysis

• Support data-driven decisions

• Promote continuous improvement

• Foster collaboration across teams

• Enhance quality, efficiency, and compliance

In today's world with growing complexities, intense competition, and increasing customer expectations, these tools can serve as a cornerstone for operational excellence and strategic transformation.

How 4C Consulting Can Help You Implement the 7 QC Tools

At 4C Consulting, we focus on integrating quality into the heart of your operations. We have successfully completed over 2,500 ISO implementations and delivered over 15,000 hours of expert training, so we have the experience and deep industry knowledge to help.

Here's how we help your journey with the 7 QC Tools:

✅ Gap Assessment – Identify where your existing processes are relative to your goals.

✅ Tailored Training – Teach your teams to properly use and maintain the QC tools with confidence.

✅ Tool Selection & Deployment – Select the appropriate tools for your specific problems.

✅ Real-Time Application Support – Get hands-on help with real-life projects.

✅ Ongoing Improvement Coaching – Foster an environment that promotes quality, spanning multiple departments.

Looking to aid with process improvement, variability reduction, and establishing an organization-wide continuous improvement culture?

Master the 7 QC Tools and more with 4C Consulting.

👉 Begin your journey to better quality today.

#7 QC Tools#Seven Quality Control Tools#7 QC Tools for Quality Improvement#Implementing 7 QC Tools#7 QC Tools Examples#Quality Management Tools

1 note

·

View note

Text

Aurobindo Pharma Job Openings in Quality Control and Quality Assurance Aurobindo Pharma is excited to announce job opportunities in Quality Control (QC) and Quality Assurance (QA) at our Jadcherla Unit in Telangana. Join a globally recognized pharmaceutical company known for its high-quality standards and commitment to innovation. Current Job Openings 1. Quality Control – Chromatography Experience Required: 3 to 7 years Location: Jadcherla Unit, Telangana Key Responsibilities: Perform routine analysis of in-process, finished, and stability samples using HPLC. Expertise in using HPLC software, particularly Empower 3, is required. Exposure to LCMS is an added advantage. Ensure compliance with cGMP and GLP standards during testing activities. Qualifications: MSc in Chemistry or B Pharmacy/M Pharmacy with relevant experience. Strong knowledge of chromatography techniques and regulatory guidelines. 2. Quality Control – Investigator Experience Required: 10 to 14 years Location: Jadcherla Unit, Telangana Key Responsibilities: Lead investigations related to Out of Specification (OOS) and Out of Trend (OOT) results. Manage Quality Management Systems (QMS) and conduct root cause analysis. Document investigation reports and implement corrective actions. Qualifications: B Pharmacy/M Pharmacy with extensive experience in quality investigations. Proven track record in managing complex investigations in a pharmaceutical setting. 3. Quality Assurance – Investigator Experience Required: 7 to 9 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage investigations related to QMS, production, and quality assurance. Independently handle USFDA audits and implement corrective actions. Conduct root cause analysis using various investigation tools and techniques. Qualifications: B Pharmacy/M Pharmacy with relevant experience in QA investigations. Strong knowledge of regulatory requirements and quality assurance processes. 4. Quality Assurance – Documentation/QMS Experience Required: 4 to 7 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage the preparation and review of Annual Product Quality Reviews (APQR). Handle QMS processes including deviations, CAPA (Corrective and Preventive Actions), and documentation. Ensure compliance with regulatory and company standards. Qualifications: B Pharmacy/M Pharmacy with hands-on experience in QA documentation and QMS. Strong understanding of documentation requirements for regulated environments. [caption id="attachment_56779" align="aligncenter" width="930"] Aurobindo Pharma Job Vacancies for Quality Control and Quality Assurance[/caption] 5. Quality Assurance – BMR and BPR Issuance Experience Required: 4 to 6 years Location: Jadcherla Unit, Telangana Key Responsibilities: Manage the issuance of Batch Manufacturing Records (BMR) and Batch Packing Records (BPR). Ensure accuracy and compliance in batch card preparation. Coordinate with production and quality teams to maintain seamless operations. Qualifications: B Pharmacy/M Pharmacy with experience in BMR/BPR issuance in a pharmaceutical setting. Familiarity with regulatory and compliance requirements for OSD formulations. How to Apply Interested candidates can share their resumes with the subject line "Application for QC/QA Position" to [email protected].

0 notes

Text

Elevating Quality with 7QC Tools Certification Consultants

In today’s competitive market, quality is paramount. Businesses must constantly strive to improve their processes, reduce defects, and enhance customer satisfaction. One effective way to achieve these goals is by leveraging the power of the 7 Quality Control (7QC) tools. These tools, when implemented correctly, can lead to significant improvements in product quality and operational efficiency. However, the successful adoption and utilization of these tools often require expert guidance. This is where 7QC Tools Certification Consultants from 4C Consulting come into play.

Understanding the 7QC Tools

The 7QC tools are a set of fundamental techniques used to identify and solve quality-related issues within an organization. They are essential for any business aiming to implement a robust quality management system. These tools include:

Cause-and-Effect Diagrams (Ishikawa/Fishbone Diagrams)

Check Sheets

Control Charts

Histograms

Pareto Charts

Scatter Diagrams

Flowcharts

These tools are designed to be simple yet powerful, enabling teams to analyze problems, monitor processes, and ensure continuous improvement.

The Role of 7QC Tools Certification Consultants

Achieving certification in the 7QC tools signifies that an organization has effectively implemented these techniques to enhance its quality control processes. However, navigating the path to certification can be challenging without the right expertise. This is where 7QC Tools Certification Consultants from 4C Consulting prove invaluable.

Expertise and Guidance

Consultants bring a wealth of knowledge and experience to the table. They understand the intricacies of each QC tool and can provide tailored guidance on how to implement them effectively within your organization. This expertise ensures that your team can utilize the tools to their full potential, leading to more accurate data analysis and better decision-making.

Training and Education

For the 7QC tools to be effective, your team needs to be well-versed in their application. Consultants from 4C Consulting offer comprehensive training programs that cover each tool in detail. These training sessions are designed to be practical and hands-on, ensuring that your team can immediately apply what they have learned to real-world scenarios.

Implementation Support

Implementing the 7QC tools requires a structured approach. Consultants work closely with your team to develop an implementation plan that aligns with your organization’s specific needs and goals. This includes identifying key areas where the tools can be applied, setting up data collection processes, and establishing monitoring systems to track progress.

Continuous Improvement

The journey to quality improvement doesn’t end with certification. Consultants provide ongoing support to ensure that your organization continues to benefit from the 7QC tools. This includes regular reviews of your processes, updates to training programs, and assistance with any challenges that arise.

Choosing 4C Consulting for 7QC Tools Certification

4C Consulting stands out as a leader in quality management consulting. With a proven track record of helping organizations achieve and maintain high standards of quality, their team of experts is well-equipped to guide you through the 7QC tools certification process.

Their approach is customized to meet the unique needs of each client, ensuring that you receive the support and guidance necessary to achieve your quality goals. By partnering with 4C Consulting, you can be confident that your organization is on the path to improved quality, efficiency, and customer satisfaction.

The 7QC tools are a powerful asset for any organization committed to quality improvement. However, their effective implementation requires expertise and guidance. 7QC Tools Certification Consultants from 4C Consulting provide the knowledge, training, and support necessary to ensure that your organization can leverage these tools to their fullest potential.

By choosing 4C Consulting, you are investing in a future of continuous improvement and operational excellence. Contact 4C Consulting today to learn more about how their 7QC Tools Certification services can benefit your organization and help you achieve your quality objectives.

0 notes

Text

How the 7 QC Tools Revolutionize Quality Management

Quality management is a crucial aspect of any organization, regardless of its size or industry. It involves the continuous monitoring and improvement of processes, products, and services to meet or exceed customer expectations. However, maintaining quality standards can be a daunting task without the right tools and techniques in place. This is where the 7 QC (Quality Control) tools come into play.

The 7 QC tools, also known as the 7 basic tools of quality, are a set of statistical tools used to identify, analyze, and solve quality-related problems. Developed by Kaoru Ishikawa in the 1950s, these tools have revolutionized the field of quality management and have become an integral part of quality improvement processes in organizations around the world.

Checkout 7 QC Tools Training by Swades QMS

The 7 QC tools consist of Pareto chart, cause and effect diagram, check sheet, control chart, histogram, scatter diagram, and flowchart. Each tool serves a specific purpose and can be applied at different stages of the quality management process. Let's take a closer look at how these tools revolutionize quality management.

1) Pareto Chart: This tool is used to identify the most significant issues or problems that need to be addressed. It follows the Pareto principle, also known as the 80/20 rule, which states that 80% of the problems are caused by 20% of the factors. By using a Pareto chart, organizations can prioritize their efforts and resources to tackle the most critical issues first.

2) Cause and Effect Diagram: Also known as the fishbone or Ishikawa diagram, this tool helps identify the root causes of a problem. It is a visual representation of all the potential causes and their relationships to the problem at hand. By analyzing the diagram, organizations can pinpoint the underlying causes and take corrective actions to eliminate them.

3) Check Sheet: This tool is used to collect data and record the frequency of a particular event or problem. It helps organizations track and monitor the occurrence of a problem over time and identify any patterns or trends. With this information, organizations can make informed decisions and take preventive measures to reduce the frequency of the problem.

Also Read: Basic Statistic Training

4) Control Chart: This tool is used to monitor and control a process over time. It helps identify any variations or abnormalities in the process and take corrective actions to keep it within the desired range. By using control charts, organizations can ensure consistency and stability in their processes, leading to improved quality.

0 notes

Text

Seven new management tools - 7QC Tools

“As much as 95 per cent of all quality-related problems in the factory can be solved with seven fundamental quantitative tools.”

-Kaoru Ishikawa, The inventor of Fishbone Diagram

In today’s customer-centric market, quality is an integral factor in the growth and sustainability of any business. Businesses go the extra mile to provide the best and excellent customer experience to ensure customer satisfaction. Hence, efficient quality management which has the highest impact on customer experience is one of the most essential features for any business.

Introduced by Kaoru Ishikawa, the seven basic tools of quality also known as 7 QC tools are very effective in quality management and quality assurance process. So, businesses who want to ensure competitive and excellent quality of their products and services can utilize the proven 7QC tools for structuring a strategic plan for quality improvement.

Types of quality management tools

Cause and Effect Diagram

Cause and Effect Diagram also known as Fishbone Diagram helps in identifying the potential causes of an effect or a problem. In addition to sorting ideas in respective categories, it also helps in understanding the areas of opportunity through effective brainstorming. Fishbone training empowers you to identify the potential cause in the problem.

Control Chart

Control charts are used to study how the processes have changed over a period of time. Further, by comparing current data to historical control limits, one could lead to the conclusion about whether the process variation is consistent as in under control or unpredictable as in out of the control due to being affected by special causes of variation.

Pareto Chart

Pareto Chart is based on the 80/20 rule where it shows the significant factors that have the highest impact on the identified problem.

Check Sheet

Check sheet is a structured process which helps to collect and analyzing data. It is an effective tool that can be for a variety of purposes.

Histogram

Histogram is commonly used a graph that shows the data and its frequency of distribution to help users identify each different value in a set of data occurs.

Scatter Diagram

Scatter diagram shows the relationship between two important factors i.e. pairs of numerical data, one variable on each axis to demonstrate the relationship.

Stratification

Stratification also known as a flow chart or run chart is a technique that separates the data gathered from a variety of sources so that patterns can be seen i.e., the path an entity has taken through a defined process.

Utilizing the 7 QC tools in six sigma or quality management process helps in taking a systematic approach to identify and understand the risk, assess the risk, control fluctuation of product quality and accordingly provide solutions to avoid future defects.

WHEN SHOULD YOU USE 7 QC TOOLS?

7 QC tools can be carried out during the quality management, quality improvement process, six sigma implementation processes or even the regular PDCA cycle for the quality purpose for enhanced quality management.

In the first phase of measuring and identifying, Fishbone Diagram also known as cause and effect diagram, Pareto Chart and Control Chart can be utilized. In the next phases of assessment and analysis, Scatter Diagram, Histogram and Checklist can be carried out. The Control Chart can be utilized consistent quality improvement.

BENEFITS OF 7 QC TOOLS

The 7 QC tools are structured and fundamental instruments that help businesses improve their management and production process for achieving enhanced product quality.

From assessing and examining the production process, identification of key challenges and problems to controlling the fluctuation present in the product quality and providing solutions for prevention of defects in future, the easy to understand and implement, 7 QC tools are very effective. Some of the major business benefits of 7 QC tools are listed below.

Provides a more structured path for problem-solving and quality improvement

Easy to understand as well as implement yet extremely effective

A scientific and logical approach for problem-solving

Follows the 80/20 rule i.e. gain 80% result with 20% efforts

Improve the quality of product and services

Helps in identifying and analyzing problems during the process

Fishbone training aides in root cause analysis and problem-solving

Encourages team spirit and fosters a healthy culture

Identifies roots cause and solve it permanently

Enhance customer experience and customer satisfaction

#types of quality management tools#data quality control tools#new seven management tools#stratification quality tool pdf#7 qc tools คือ#7 new tools#seven new management tools

1 note

·

View note

Video

youtube

Convert Any Cursive Image to Notepad Plus .wrt & Pixcel Notepad .nts format with Encryptor Software

Contact us at: 7428811442 ( Whatsapp/Call) for purchase and enquiries @intellitechdataservices Email:- [email protected] Website:- https://intellitechdataser.wixsite.co... #starttxt #pixcel #nts #wrt Conversion Software with 100% non detection gurantee. Buy it Now!!! Bulk Text Encryptor is Developed by INTELLITECH DATA-SERVICES in 2017 for Data Entry Notepads like #notepadplus #pixcel #rtxnotepad #notepadrt #blendnotepad #pxnotepad etc. This is 100% Safe and Fastest Solution than any third party applications like autotypers and mods. Third Party Softwares and Autotyping Softwares are already Banned by Data Entry companies since they are easily detectable in the QC ( Quality Checking). Bulk Text Encryptor is not only safe from detection by ensures that the Encryption remains same according to the company notepad. Bulk Text Encryptor has inbuilt Company Notepad (Viewer Editor) Bulk Text Encryptor can convert 1000 pages into company notepads in just 1 minutes. Available in One or Two Year License. .wrt .nts .px .tst .txt .nts .xtt #imagetoword #converthandwritingtotextdocument #imagetoword #howtoconverthandwritingtotext #howtocopytextfromhandwritingimage #howtoconvertimagetotext #convertimagetotext #hathselikhehuekowordmekaisebadle #converthandwritingtotext #handwritingtotext #howtoconverthandwritingtotext #howtocopytextfromhandwritingimage #howtoconvertimagetotext #convertimagetotext #hathselikhehuekowordmekaisebadle #converthandwritingtotext #handwritingtotext #howtocopytextfromimage #jpgtoword #jpegtotext #ConvertImageto Word Document #convertimagetoeditabletext How to convert Image to Notepad Plus? How to convert Jpeg to Notepad Plus? How to copy paste text in Notepad Plus? How to edit text in Pixcel Notepad? How to save text in Pixcel? How to install Pixcel Software? How to transfer text in Notepad Plus? How to get text from Images? How to convert Image to typing? How to convert Image to Notepad? How to convert Images to Notepad? Pixcel Hacks Pixcel Tips Pixcel Tricks Pixel Download Pixel Install Pixcel 2023 pixel.exe Pixcel.exe How to Convert Image to nts? How to Convert Jpg to nts? How to Convert JPEG to Nts Nts Convertor Software Pixcel Convertor Software Pixcel Conversion Software Pixcel Typer Pixcel Autotyper Pixcel Encryptor Pixcel All Hacks Pixcel Notepad Enable Copy Paste Option Pixcel India Pixcel Data Entry Pixcel Typing Pixcel Fast typing Pixcel Fast typer Pixcel Automatic Tying Starttxt Tutorial Pixcel Pixcel Tutorial Pixcel Pixcel Tutorial How to install Pixcel Notepad Software? Pixcel Introduction How to Install Pixcel on Windows 11? How to Install Pixcel on Windows 10? Pixcel Basics Pixcel Notepad Coding Pixcel Notepad Latest Version Pdf to Pixcel Notepad Installing and Uninstalling Pixcel Notepad Pixcel App Pixcel Application How to Install Pixcel on Windows 7? How to Install Pixcel on Windows 8? How to use Pixcel? How to check errors in Pixcel? How to find errors in Pixcel? Pixcel Error checking? Pixcel Qc Software How to Save text in Pixcel? Pixcel Free Software Pixcel free trick Pixcel free Autotyper Pixcel free Autotyping Software Pixcel free Download Pixcel free hack Pixcel Mod Pixcel Latest Mod Pixcel downloads download Pixcel for windows download Pixcel for windows 10 installing Pixcel Pixcel download for windows 10 64 bit free download of Pixcel edit with Pixcel Pixcel download Pixcel windows 7 Pixcel download Pixcel online Pixcel apk Pixcel.exe Pixcel features How to add notes in Pixcel Notepad Pixcel Macro How to use Pixcel Notepad on Mac? Pixcel comparison tool Download Pixcel Convertor, Download Pixcel, pixcel download, pixcel trick, pixcel india, pixcel hyderabad, pixcel shortcut, pixcel macro, pixcel editor, pixcel windows 10, pixcel windows 11 pixcel windows, pixcel convertor download, pixcel typing software free pixcel app pixcel app convertor pixcel.exe convertor

1 note

·

View note

Note

I'm sorry this feels real weird, but I love PINTWILF a lot, and the fact that you really expanded on SQH's role and everything. And I really loved that you added the other unnamed peaks and melded them in, everything that you wrote about the peaks actually really fleshed them out and their roles. So what did you name the three other peaks, and what are their roles? I think I only really understand that Xi Jiao is an animal/beast peak?

It’s not weird! I’m quite pleased with the sect logistics I’ve been writing in PINTWILF (from a humor angle, not a realism angle) and so I’m happy to talk about it. This is the order of peaks I’ve been using in PINTWILF:

(1) Qiong Ding Peak - Peak Lord: Yue Qingyuan (Canon)

Apparently they’re responsible for general affairs. I’ve always assumed they’re also responsible for dealing with other sects and politics, outside of peak-specific specialties where another peak lord has the authority to represent the sect.

(2) Qing Jing Peak - Peak Lord: Shen Qingqiu (Canon)

Peak of scholars and strategists. I assumed from there that they would also be responsible for a lot of library and archive-related duties, and that they would have some talisman and seal experts, etc., and that QJ and QD would be closely tied in many matters.

(3) Wan Jian Peak - Peak Lord: Wei Qingwei (Canon)

Peak of sword masters. I assumed that this meant both martial weapon specialists and sword smiths. I also assumed that this could be expanded to many kinds of metal work. Where WJ and AD meet is probably where a lot of non-weapon-related fabrication happens.

(4) An Ding Peak - Peak Lord: Shang Qinghua (Canon, minus #?)

I’ve seen people put An Ding anywhere from 4th to 12th. I’m not sure that An Ding has a canonical number. I prefer An Ding being 4th because of 1) how closely Qiong Ding and An Ding’s work would be tied and the importance of logistics, but 2) mainly how funny I think it is if SQH is only three murders away from being the sect leader.

SQH: “Wei Qingwei, you cannot die. The chances of Shen Qingqiu and Yue Qingyuan offing each other is too high for you to die on me. YOU’RE MY LAST LINE OF DEFENSE. DON’T MAKE ME BE SECT LEADER.”

(5) Xian Shu Peak - Peak Lord: Qi Qingqi (Canon)

It’s unclear what specialties XS has, probably because it only existed in PIDW as the “hot lady peak” (and MXTX never actually expanded it post-transmigration). It’s never come up, but I kind of dig the idea of XS doing some textiles work, anything from weaving fine fabrics to rope-making. (Who makes stuff like Immortal Binding Cables? It could be Xian Shu.)

(6) Xi Jiao Peak - Peak Lord: Tang Qingling (Non-Canon)

Yes, this is an animal/beast peak, because I’ve seen it brought up in a few fics, and I thought it would be funny for SY to be entranced by the idea, only for SQH to go, “Bro, I hope you have the stomach for blood and literal shit, because that’s where they butcher monsters for parts and collect crap for fertilizer.”

I also like the idea of Cang Qiong Mountain Sect having actual pipelines based on the specialties, which make it a very profitable and efficient sect. (Also, where are they getting their food? Do they have livestock? Do they buy it all from the surrounding towns and cities? Xi Jiao is me deciding that, yes, they have livestock.) Liu Qingge brings in a monster, it goes to Xi Jiao, then the parts go out again to Wan Jian, Qian Cao, Zui Xian, and others. to become armor, medicine, potions, etc.. Or maybe just to An Ding to sell.

(7) Bai Zhan Peak - Peak Lord: Liu Qingge (Canon)

They make people who fight good.

(8) Qian Cao Peak - Peak Lord: Mu Qingfang (Canon)

Trains healers and makes medicine. I assumed that they would grow as many of their own plants as they could and do a lot of plant breeding. Medicine could also be a great source of income for the sect (another reason why QC is one of Shang Qinghua’s favorite peaks).

(9) Ku Xing Peak - Peak Lord: Wang Qingjie (Canon, minus # and peak lord)

The peak name is canon, but I can’t remember if they have a canonical number and they don’t have a canonical peak lord. They’re all all-male peak with an ascetic lifestyle, living akin to monks.

I think I decided that they specialized in talismans and the creation of other spiritual tools, including and as well as ceramics. So, they work closely with many of the other peaks, but especially An Ding in supplying other peaks. I can’t remember why I decided this. I think maybe I decided that Ku Xing might have a philosophy that “to create purifying objects, the maker must also be free from impurities”? Hence the ascetic lifestyle.

I also thought it would be funny if Ku Xing and Qing Jing had a little bit of a rivalry going on. Shen Qingqiu makes very good talismans and Wang Qingjie is NOT angry about it (in the way of someone trying not to be angry).

(10) Zui Xian Peak - Peak Lord: Zhang Qingyan (Canon, minus # and peak lord)

Again, the peak name is canon, but I can’t remember if they have a canonical number and they don’t have a canonical peak lord. This is the peak that apparently specializes in alcohol.

So, I decided that they might as well be responsible for brewing other potions and solutions. Maybe they have people who specialize in alchemy. Qian Cao and Wan Jian and Xi Jiao (and nearly every other peak) probably do their own brewing of certain things, but it probably helps to have someone else dedicated to brewing on a large scale. Qian Cao grows the plants for a common medicine, then ships them to Zui Xian for mass-production, and the An Ding takes the result and sells it to all the nearby towns and cities.

Zui Xian probably saves and makes Cang Qiong so much money.

(11) Long Sheng Peak - Peak Lord: ??? (Non-Canon)

This is a newer invention and I haven’t come up with a peak lord yet, but they’re named after “The Dragon’s Backbone” and they specialize in plants and agriculture. This is my “this is how the sect gets fed” peak, alongside Xi Jiao.